3D bio printer

3D bio printer (3D bio-printer; 3D biology printer) is a kind of can under the drive of the digital three-dimensional model, in accordance with the principle of increasing material manufacturing assembly positioning biomaterials or cell, manufacturing medical devices, tissue engineering scaffolds and tissue products and equipment.

Organ transplantation can save many patients whose organs are damaged or damaged, but this technique also has some disadvantages, such as insufficient organ source and difficult to avoid rejection. However, with the advent of the future "bio printer", these problems have been solved with new technical means.

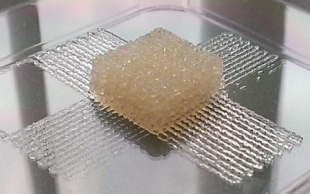

This machine first reads a medical image data reconstruction of 3D model or design, the model of multiple layers, the computer control of print head layer "print" print by biological materials or cellular bio ink, we repeat this process until the completion of the three-dimensional tissue precursor print. The cells then re organize, fuse, and form new blood vessels and other tissue structures.

In an interview with engineers, Keith Murphy, chief executive of Organovo, pointed out that one day, just by pressing the button lightly, the 3D bio printer could produce the organs we need.

3D bio printing a technical concept is the first by the United States Clemson University, University of Missouri, Drexel University, a professor at the University of proposed around 2000, 2003 Mironv V and Boland T in Trends in Biotechnology magazine "3D printing organ system put forward this concept.

In 2010, Organovo launched a 3D bio printer that could help users build biological tissue for research and development. In November 2014, Organovo launched its commercially available 3D print human liver tissue, exVive3DTM, for preclinical drug testing.

In October 10, 2015, Regenvov launched the third generation bio 3D printing workstation. With this bio 3D printing device, a batch of "print out" liver units was successfully used for drug screening.

Composition structure

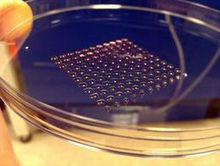

3D bio printers, based on existing technology, are now being used to build 3D models of industrial components. The difference between biological printers is that they do not use layers of plastic, but instead use layers of biological material or cell blocks to make real living tissue

3D bio printers can have multiple print nozzles, which can print human cells, known as "bio ink", and also print pure biological materials called bio paper". The so-called biological paper is actually the main ingredient is hydrogel, which can be used as a scaffold for cell growth. The 3D bio printer uses cells from the patient's own body, so it does not produce rejection.

Development prospect

In an open letter published in the May 2013 issue of the new England Journal of medicine, scientists succeeded in implanting 3D printed tracheal stents into babies.

David David Topf, a medical scientist at Ann Arbor, University of Michigan, described the transplant with A.Zopf. The transplanted infant suffered from local bronchial degeneration, and the absorbable stent used in surgery consisted of polycaprolactone.

The mother noted that the mother gave birth to the baby boy named Kaiba Gionfriddo at 35 weeks of gestation and appeared to be in good health but appeared to have sunken chest walls and breathing difficulties after 6 weeks. This situation means that endotracheal intubation is required before 2 months of age to maintain ventilation. Therefore, they designed a model of tracheal stent for children using a computer, using a thermoplastic bioabsorbable material, and fabricated a tracheal stent by laser sintering. In transplantation, the trachea is fixed by a hole in the stent. 7 days after placement of the stent, mechanical ventilators were gradually removed, and ventilator support was completely stopped 21 days after surgery. A year later, the left main bronchi of the children were observed by endoscopic surgery, and everything was normal. So far, there have been no stent related problems.

At present, scientists use biomedical polymer materials, inorganic materials, hydrogel materials or living cells, have successfully printed a smaller proportion of human ear cartilage tissue, liver cells.

The biological 3D printer has the characteristics of biological print various kinds of materials, the cell damage rate is low, the printing precision and convenience of operation, but also under sterile conditions and cell biological material 3D printing, and a new temperature control unit and the print head design, can support a variety of biological materials from 5 DEG C to 260 DEG C molten printing.

Biological 3D printing supports live cell printing, with printed cells having a survival rate of up to 90%. Currently, the printed cells live for up to 4 months. However, it is a long way to go from human cells, tissues and even organs to be printed out and applied to clinical practice. This requires collaboration among scientists in many fields.

- Previous article:Period

- Next article:Bio ink

English

中文

English

中文